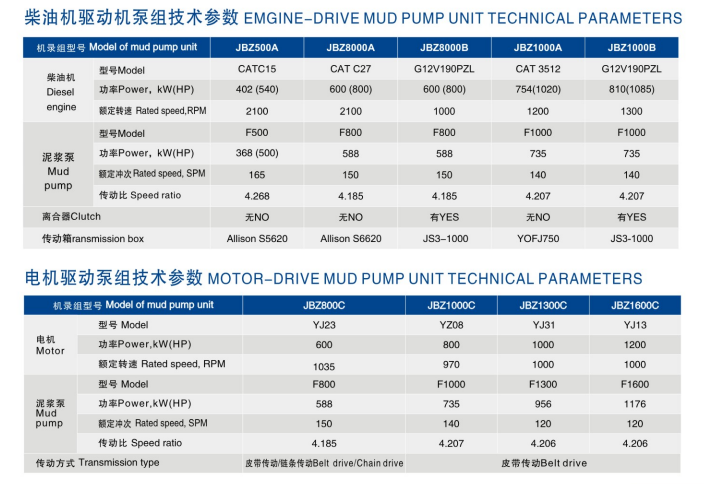

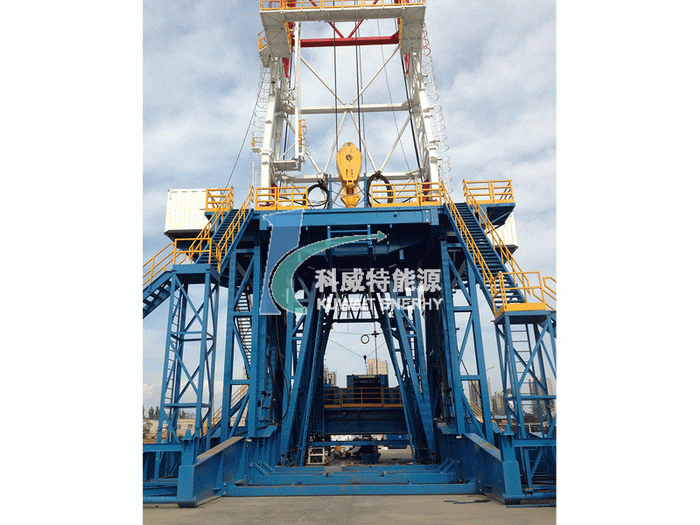

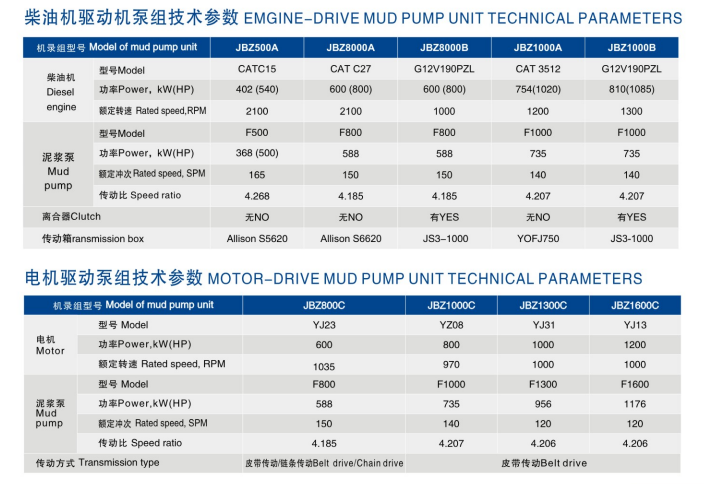

The mud pump set can be matched with various types of drilling or well repair machines. Power can be either diesel engine driven or electric driven; There are various forms of transmission, such as belt and chain transmission, gear transmission, and transmission shaft. The movement mode is divided into two types: pry mounted and trailer mounted. Various supporting facilities such as rain, sand, and cold protection can be configured according to the special needs of users.

parts

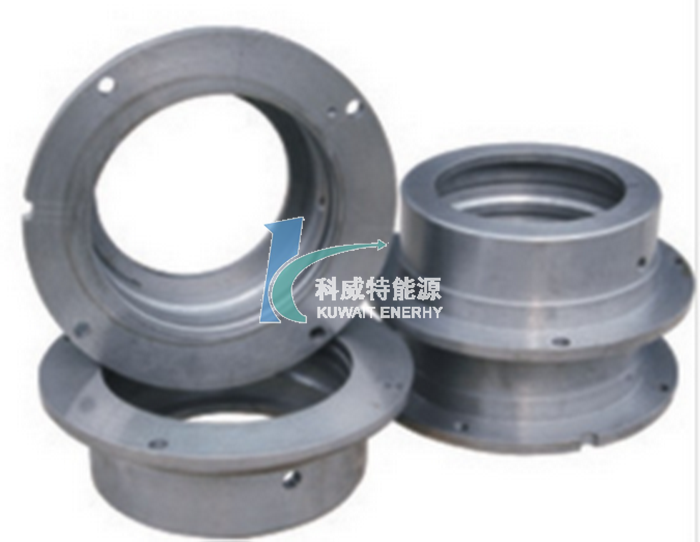

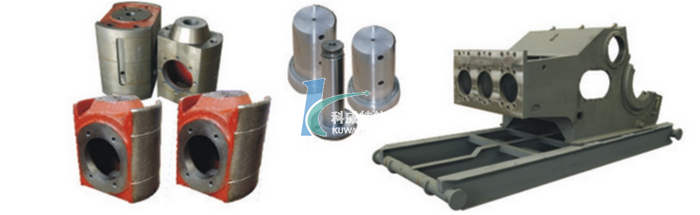

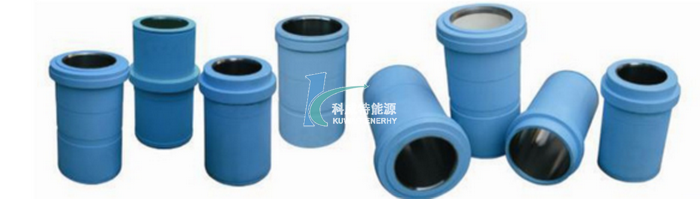

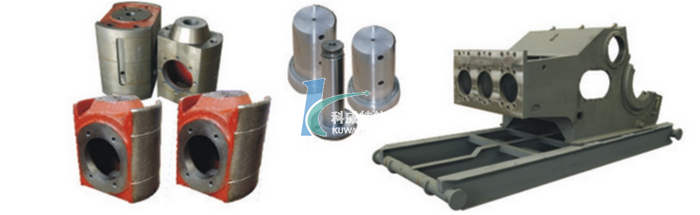

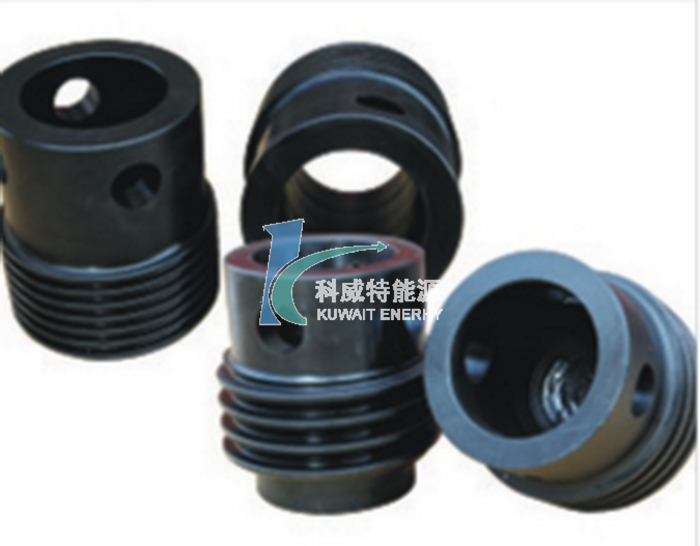

Hydraulic cylinder and cylinder assembly

The material of the hydraulic cylinder is specially made alloy steel forgings and processed using mature scientific processes, with a reasonable structure and high efficiency.

The hydraulic cylinder assembly is equipped with corresponding bolts and nuts.

The material of the hydraulic cylinder is alloy steel forgings, and the three hydraulic cylinders of each pump can be interchanged. If requested by the user, the surface of the hydraulic cylinder can be chemically plated with nickel to enhance its corrosion resistance.

The discharge port is equipped with an air bag, a shear pin safety valve, and a discharge filter screen.

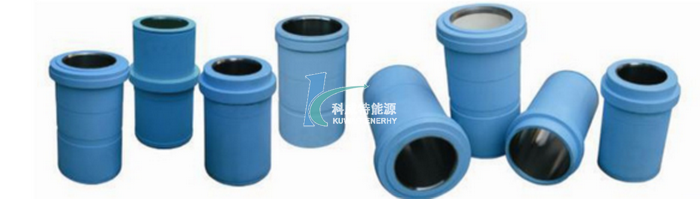

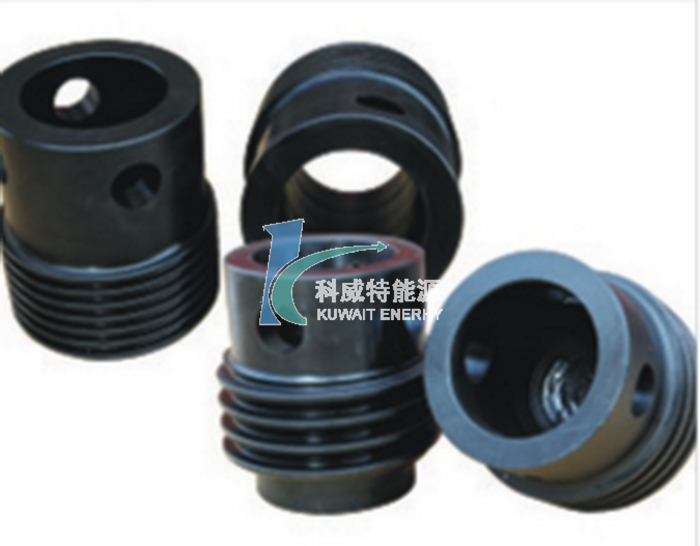

Bimetallic steel sleeve

The bimetallic steel sleeve is composed of two types of metals: inner and outer. The outer layer is made of high-quality carbon steel, and the inner layer is made of high chromium resistant alloy iron. The hardness of the inner layer at the hot spot reaches HRC62 or above, and the inner surface is smooth and mirror like. The size tolerance of the inner hole is strict, and the normal service life can reach more than 800 hours.

crankshaft

The crankshaft is made of alloy steel castings. The crankshaft is equipped with large gear rings, connecting rods, bearings, etc. The tooth shape of the large gear ring is a herringbone tooth, and the inner hole of the large gear ring is an interference fit with the crankshaft, which is fastened with bolts and anti loosening nuts. The large end of the connecting rod is installed on the three eccentric cranks of the crankshaft through a single row of short cylindrical roller bearings, while the small end of the connecting rod is installed on the crosshead pin through a double row of long cylindrical roller bearings. The two ends of the crankshaft are double row radial spherical roller bearings.

Guide plate

The guide plate is made of high-quality materials and processed through specific processes, with mechanical properties reaching σ≥ 250MPa.

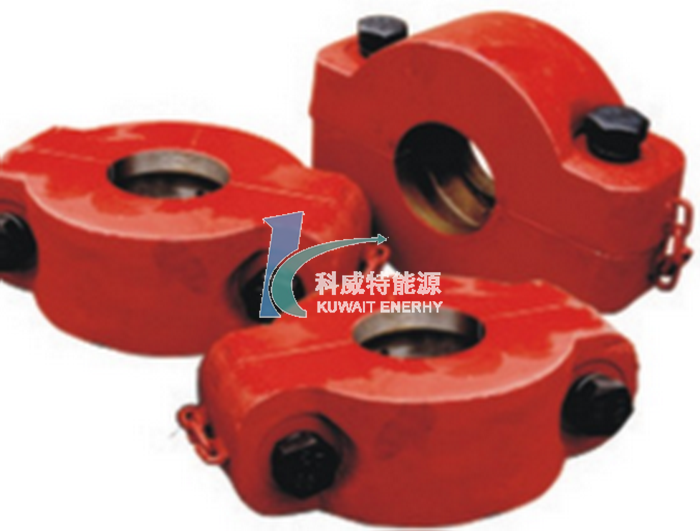

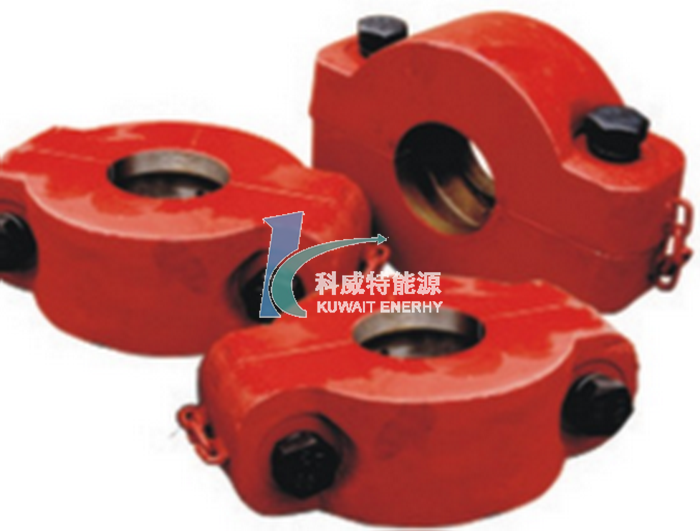

Shear pin safety valve

JA-3 piston shear pin safety valve, suitable for high-pressure jet drilling machines that are currently widely promoted; It can also be used in high-pressure circulation systems for other media such as oil and water. Compared with spring and diaphragm safety valves, this valve has the following characteristics: 1. Flexible opening and closing; 2. The pressure bearing piston has a small area; 3. Easy to reset; 4. Good versatility, can be connected to various pumps.

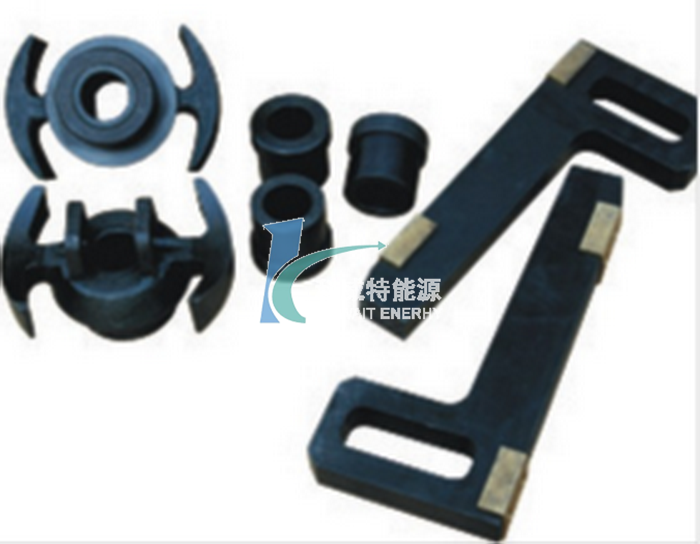

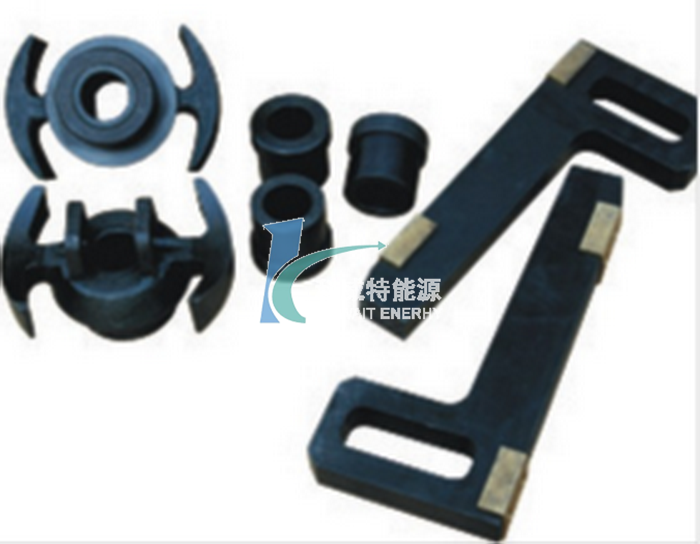

Mud pump intermediate rod, crosshead, crosshead pin

The material of the crosshead and crosshead guide plate is made of American ASTM A448-83 impregnated cast iron, which has good wear resistance and long service life. Except for the F-500 pump which adopts a guide vane structure, other mud pumps adopt an upper and lower guide vane structure, which can be adjusted for concentricity by adding shims at the lower guide vane. The flange bolt connection between the crosshead and the middle pull rod is a pinhole fit. This rigid connection method ensures the concentricity between the middle pull rod and the crosshead. The middle pull rod is connected to the piston rod with a lightweight clamp, making the connection between the middle pull rod and the piston rod convenient and reliable.

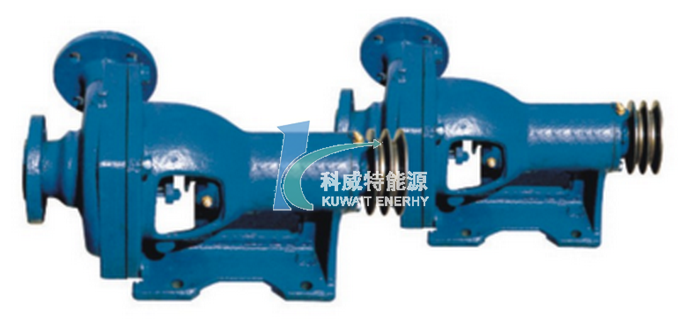

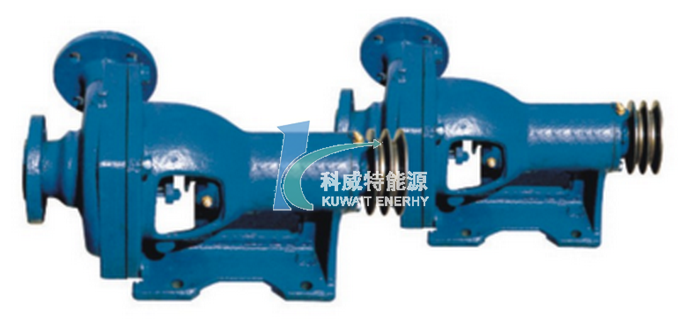

Spray pump

The spray pump adopts a single-stage single suction horizontal cantilever centrifugal pump. Mainly used for spraying, cooling, and lubrication of oil drilling pump cylinder liners and pistons, and can also be used to transport clean water below 80 ℃ or wastewater containing a small amount of mud and sand. When used in conjunction with oil drilling pumps, spray pumps are driven by belts and can also be directly connected to motors in other locations.

2S gear pump

Air bag

Insert board assembly, upper and lower guides

Clamp

、 、

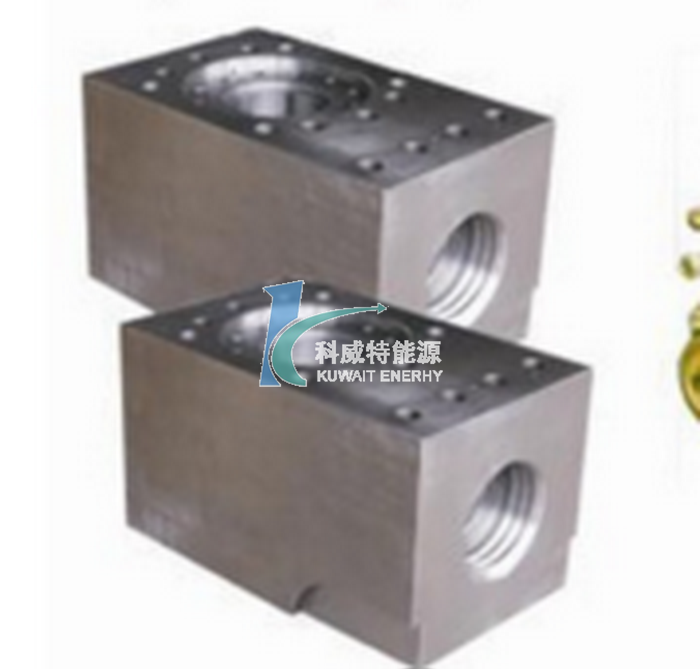

Cylinder head, valve cover

Packing box

|