Home >> Products >> Power equipment products

Intelligent insulation tool cabinet

Intelligent insulation tool cabinet is a cabinet device that measures the temperature and humidity inside and outside the insulation tool cabinet, and...

Intelligent insulation tool cabinet is a cabinet device that measures the temperature and humidity inside and outside the insulation tool cabinet, and controls heating, dehumidification, ventilation, etc. based on the requirements of live working tools for the storage environment. It adopts intelligent temperature and humidity measurement and control technology, condensation dehumidification, self heating and drying technology, large air circulation technology, remote sensing, remote signaling, remote control, and remote adjustment technology, as well as backend management software technology. It realizes a small environment for storing electrical safety tools that is temperature and humidity balanced, controllable, and can self adjust according to environmental changes. At the same time, it has certain tool management functions. It has the characteristics of strong functionality, flexible handling, and simple maintenance, which solves the problem of storing electrical safety tools and equipment in substations and grassroots teams at all levels, and also solves the problem of long-distance and long-term live work. Functional features: 1、 The assembled internal structure can simultaneously store tools and supplies such as insulated rods, electrical testers, grounding wires, insulated gloves, insulated boots, etc., achieving comprehensive utilization. 2、 Provide a small environment suitable for storing insulated tools to meet the needs of rapid and repeated use. 3、 The rotatable hanging device meets the requirements of hanging insulated boots and gloves upside down, and can also adapt to different hanging needs by adjusting the angle of the hanging rod. 4、 Can be equipped with networked insulation tool management software to achieve tracking and management of the safety life cycle of insulation tools. 5、 Can be controlled automatically or manually; We use industrial grade microcomputers to process digital sensor temperature and humidity data, and through intelligent control based on fuzzy algorithms, we effectively control the operation of dehumidification and hot air circulation systems, achieving the purpose of dehumidification while ensuring that the temperature inside the cabinet is not too high. 6、 Ensure that tools are not frosted when removed from the cabinet; Equipped with leakage protection devices to ensure personnel safety. 7、 Set up an ultra humidity protection device independent of the control system, which can ensure that the temperature inside the cabinet does not exceed the limit even if the control system fails. 8、 The control parameters can be manually set, but the temperature setting should not exceed 35 degrees. Both manual setting and intelligent control work together to protect the tools and instruments inside the cabinet from damage due to high temperatures. 9、 Equipped with communication interfaces, it can achieve networked remote monitoring, and users can remotely monitor the temperature and humidity inside the tool cabinet;

10、 Identify and classify insulation tools to meet the requirements of fixed position management, and avoid safety accidents caused by incorrect handling and placement of tools.

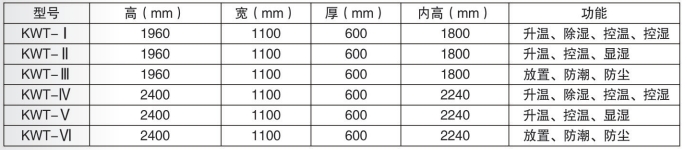

Technical specifications:

|